Packaging costs

In case of order, a packaging fee will be charged for the delivered products. The packaging cost is determined on the basis of the net filling weight of the goods.

| Packaging costs | |

| Package net filler weight | Net packaging cost (HUF) |

| 1- 100 kg | HUF 390 |

| 101- 480 kg | HUF 690 |

| 481- 960 kg | HUF 1.290 |

| 961-1440 kg | HUF 1.990 |

| 1441-1920 kg | HUF 2.690 |

ATTENTION! Please note the load weight limits for packaging when ordering:

- When ordering 1 kg packages, the maximum load capacity of 1 carton can be 6 x 1 kg of product, i.e. a total of 6 kg.

- When ordering 1 kg packages, the maximum load capacity of 1 package can be 18 x 1 kg of product, i.e. a total of 18 kg.

- When ordering 20 kg packaging units, the maximum load capacity of 1 pallet can be 24 20 kg products, i.e. a total of 480 kg.

You can read more about the method of packaging, parts of the packaging, labels, markings below.

Method of packaging

For products covered by ADR

In the case of parcel transport, the goods must in all cases be placed in qualified packaging, the purpose of which is to guarantee safety.

Based on the code on the packaging, it is possible to identify how durable the given packaging is, so what type and properties of dangerous goods can be loaded into the given packaging.

| Letter marking on the packaging | Goods classification according to the packaging | Quality of packaging |

| X | I., II., III. | very strong |

| Y | II., III. | strong |

| Z | III. | less strong |

The codes on the package always start with the ”  ” symbol.

” symbol.

Parcel delivery

Dangerous goods transported in closed packaging:

- On its own (eg barrel, jug, composite IBC with plastic container inside, metal frame outside)

- Composite packaging (outer and inner packaging, which is inseparable)

- Combined packaging (double packaging, simultaneous use of inner and outer packaging)

- United packaging (any combination of the above packaging methods, in a unit load, ie the transport of several goods in one unit, e.g. goods wrapped in foil on a pallet, goods placed in a box).

For products that can be shipped in limited quantities (LQ)

Only parcels in combination packaging may be submitted.

According to the packaging, a relatively small quantity of dangerous goods is placed in a so-called inner packaging, of which a total of so much can be placed in a common outer packaging, such as a paper box, so that the total gross weight of the combined packaging (piece) does not exceed 30 kg. The relative stiffness of the resulting package and the small (limited) quantities of goods in the inner packaging together significantly reduce the risk of the material during transport.

Parts of packaging

During transport, the inner packaging must ensure the protection of the consignment.

Proper inner packaging should be able to protect the product from shocks and impacts. Packaging must be filled in such a way as to prevent any leakage or spillage of the contents of the consignments ready for transport, which may result in particular from changes in temperature, humidity or pressure.

Use of filler

Basically, the product should be surrounded on all sides by a space-filling material inside the inner packaging so as to prevent the product from moving inside the packaging and coming into direct contact with the packaging material. The filling material must be absorbent and, when selected, it is important that it does not react with the filling material in the event of an accident, and that it must be able to absorb the leaking hazardous material to a certain extent and quantity.

Due to the fact that the outer packaging has been manufactured for the size and shape of our products, therefore we do not have the possibility to use filler material.

The outer packaging that fits the inner packaging prevents the product from moving inside the packaging.

Adherence to the degree of filling and the load capacity of the consignment

- the safe transport of the products can be guaranteed with adequate space filling

- overfilling or insufficient use of the filling material or overloading the package can result in damage to the product.

Outer packaging

Groupage transport and industrial loading technology require easy-to-handle stackable form-fitting packaging.

Form-fitting packaging appropriate to the nature of the goods

The packaging must comply with the requirement to preserve the integrity of the contents and ensure the protection of the environment of the packaging during contact with other packages (stacking) or against the physical effects necessarily arising from industrial packaging handling, and, in accordance with the relevant provisions of the ADR.

Labels, dockets, markings

Labels

The labels on our products are in Hungarian and contain the required data in accordance with legal regulations. The indicated data includes the name of the product, its composition, the name of the field of application, the list of the antimicrobial spectrum, the most important parameters of the application (application concentrations, exposure times), the production time (which can be read from the LOT number, expiration date, the H and P phrases for safe use, based on the 44/2000 (XII.27.) regulation danger symbols and signs, the name of the manufacturer, distributor, the number of OTH licenses, as well as the Hungarian Instructions for Use (Instructions for Use) approved by OTH.

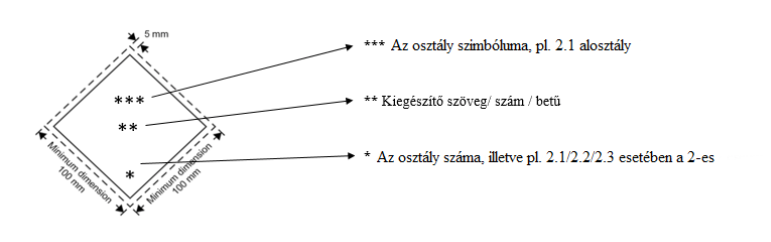

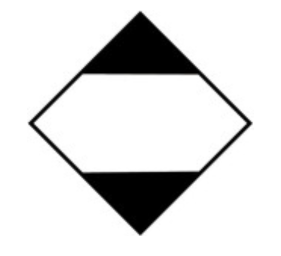

Danger labels

- indications required by ADR

- vertex square / rhombus

- smallest minimum size: 100 × 100 mm

- framing line thickness minimum 2 mm

- an inner line runs 5 mm inside the outlines

- proportions must be maintained when reducing the size

- in the case of vehicles and containers, the size of the large docket, i.e. 25 × 25 cm is necessary

The white-based pictogram is located on the product itself and is intended for consumers. The danger symbols are for consumer information only, so they are NOT equivalent to the markings required by the ADR, the dockets!

Markings

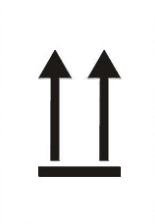

The markings on dangerous goods must be affixed to the outer packaging in such a way that they cannot be obscured by other markings. The trade mark and the orientation arrows must appear on each side of the box.

In the case of transport in limited quantities, the exemption marking must appear on the packaging:

Marking for road transport

The size of the marking is specified, at least 100 x 100 mm, which can be reduced to a maximum of 50 x 50 mm, the minimum thickness of the framing lines is 2 mm.

In the case of liquid material, the standing position arrows must also be indicated to warn of the risk of leakage. It is used when it is not visible from the outside in inner packagings with a removable lid.

Mandatory on the two opposite sides of the consignment. Specifies the correct direction. It can be black or red, it can be printed on the packaging at the factory.